Corrosion tests in artificial atmospheres-Salt spray test chamber

Function

Salt spray test chamber is used for the quality inspection and salt

corrosion resistance test of a variety of materials, including

metal plating, metal, electronic components, chemical coatings,

paint, automobiles, motorcycles, metal ware, screws, springs,

magnetic materials, organic and inorganic coating, anodizing,

anti-rust oil industry etc. after the surface treatment.

It can meet a number of tests such as neutral salt spray (NSS),

acid salt spray (ASS), and copper acceleration (CASS). It is the

most cost-effective product for the salt spray corrosion test.

Testing method

Neutral salt spray test (NSS test), acetic acid salt spray test

(AASS test), salt spray test (SS test), copper accelerated acetic

acid salt spray test method for salt spray test (CASS test) and so

on; (For CASS test, we recommend the PP material or thickening PVC

chamber with high temperature resistance)

Technical parameters

MODEL | JSX-SH-120 |

| Temperature inside chamber | 35℃±1℃/ 50℃±1℃ |

| Temperature of pressure barrel | 47℃±1℃/ 63℃±1℃ |

| Inner size | W120× D80× H60cm / W120 x D100 x H50cm |

| External size | 190×105×128 (W×D×H)cm |

| Temperature Uniformity | ≤±2℃ |

| Uniformity Fluctuation | ≤±0.5℃ |

| Salt fog settlement | 1~2ml/h.80cm2 |

| Compressed air pressure | 1.00±0.01kgf/cm² |

Humid. range | ≥93%R.H, can not control |

Controller time shown | 9.9s~9990hrs |

Timer | 0~9999hrs |

Specimen holder | It can meet the tilt test at 15 ℃ ~ 30 ℃ (two layers) |

Air compressor | V-0.013/12.5(Customer provided) |

Discharge pressure | 1.25M |

Flow amount | 0.13m3/min |

Spray mode | Continuous or intermittent spray optional |

Power supply | AC 220V 50/60Hz 3.5KW |

According to CSN, JIS, ASTM standards, can be set to constant

temperature control:

- Brine spray test: NSS (neutral); AASS (acid)

- Temp. inside chamber: 35 ℃ ± 1 ℃

- Pressure air bucket: 47 ℃ ± 1 ℃

- Corrosion resistance test: CASS (copper acceleration), (For CASS test, we recommend the PP material or thickening PVC

chamber with high temperature resistance)

- Temp. inside chamber: 50 ° C ± 1 ° C

- Pressure air bucket: 63 ℃ ± 1 ℃

Heating system

The heater is made of advanced titanium protective tube, built-in

nickel-chromium alloy infrared heater core. Heating up fast which

reduce the standby time and make uniform temperature distribution,

with P.I.D + SSR control.

Cover-open method

SNS cylinder lift mode, through the SNS switch solenoid valve

control, the user can press the button switch simply, the cylinder

can open or close the cover automatically.

External material process

Paint production process, plus a layer of PP bag slot, which

effectively avoid rust caused by paint drop, corrosion and other

defects; inside and outside the box adopts PVC board reinforcement,

which is not easy to deformation.

Replenishment function

Automatic water function when the chamber and pressure bucket with

water level is low, don’t need to add water manually.

Executive standard

The chamber conforms to:

GB/T 2423.17 Basic test procedures for electric and electronic

products Ka"- salt spray test methods;

GB/T 10125 Corrosion tests in artificial atmospheres – salt spray

tests;

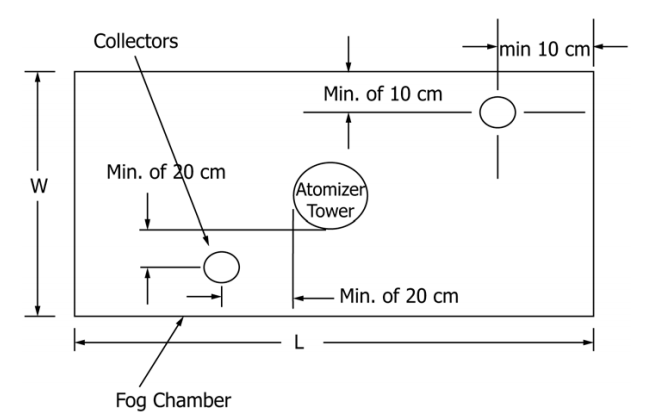

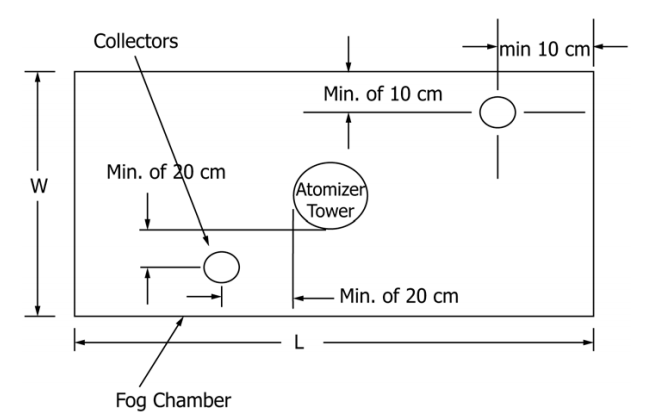

ISO 9227 Corrosion tests in artificial atmospheres (Note: 2 collection device is required, for models bigger than 108

liters (model number ZH-SH-90/90A) only; In some versions, it

specifies over 400liters is necessary)

ASTM B117-18 Standard Practice for Operating Salt Spray (Fog)

Apparatus (Note: 2 collection device is required)

ASTM B368 Test Method for Copper-Accelerated Acetic Acid-Salt Spray

(Fog) Testing (CASS Test);

JIS Z2371-2000 Methods of salt spray testing etc.